Yongjiu Memory Foam for insole material

Memory foam is a viscoelastic open-cell polyurethane renowned for its ability to mold to pressure and temperature, delivering customized cushioning and pressure relief across diverse applications. Since its introduction in bedding by Tempur-Pedic in 1991, the global shape memory foam market has expanded rapidly—expected to grow from $10.54 billion in 2024 to $12.11 billion in 2025 (CAGR 14.8 %). Innovations in sustainable bio-based formulations, 3D-printable foams, and digital design tools are reshaping the landscape, enabling new uses from insoles and sockliners to bag pads, glove inserts, and even wearable electronics. As a manufacturer, Yongjiu offers precision-cut memory foam sheets (50–90 kg/m³; 70–90 ILD Asker F) with FOB Xiamen shipping, 30 % T/T deposit, MOQ 22.4 m³, and 5–7 business-day lead times—ideal for B2B partners seeking performance, sustainability, and supply-chain reliability.

1. What Is Memory Foam?

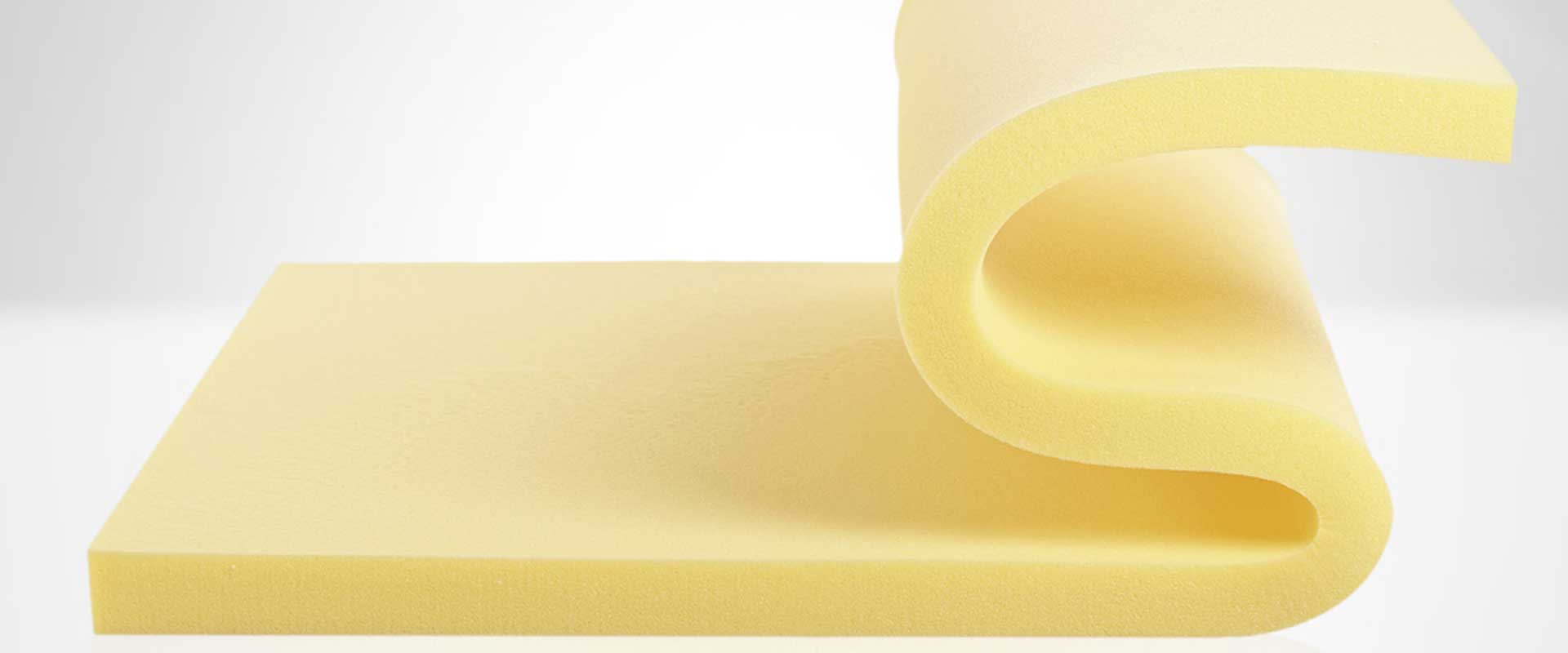

Memory foam originates from NASA-funded research in the 1970s and was commercialized for mattresses in the 1980s by Fagerdala. Its unique viscoelasticity comes from a polyurethane base blended with specific additives (polyols, diisocyanates, and temperature-sensitive agents) that slow its recovery after compression. The result is adaptive contouring—the foam softens where heat and pressure are applied, then gradually regains shape when the load is removed.

2. Manufacturing & Sustainable Innovations

2.1 Modern Production Techniques

Memory foam production begins by reacting polyols with diisocyanates, generating a viscous prepolymer that is expanded into an open-cell structure using water or other blowing agents. Advanced horizontal foaming lines then cure, trim, and cut the foam into precise sheets.

2.2 Bio-Based & Green Foams

Industry leaders are replacing up to 50 % of petroleum-derived polyols with plant-based oils (soybean, castor) to reduce VOCs and improve environmental profiles. Concurrently, recycled and upcycled materials are being incorporated—scrap foam from production can be reblended into new sheets, supporting zero-waste goals.

3. Market Trends & Growth

The global shape memory foam market is projected to exceed $12 billion by 2025, driven by rising disposable incomes, e-commerce expansion, an aging population requiring medical cushions, and increased wellness spending. Innovations such as programmable 3D-printed foams (e.g., CreateitREAL’s Programmable Foam®) enable bespoke hardness gradients and zero-waste manufacturing. Meanwhile, Layfomm sponge filament brings viscoelastic properties to desktop 3D printing, broadening prototyping possibilities.

4. Cutting-Edge Applications

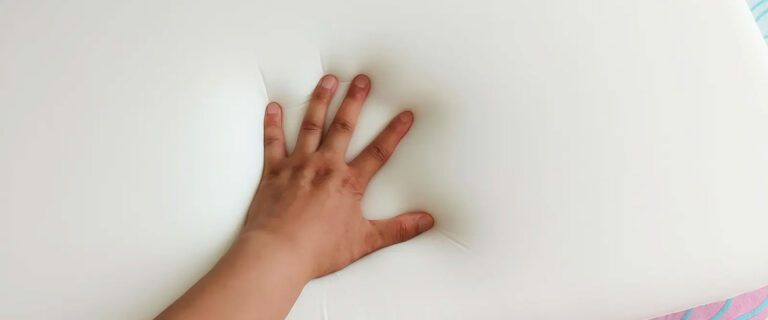

4.1 Footwear & Insoles

Memory foam sheets (50–90 kg/m³; 70–90 ILD) are cut into sockliners and insoles, where they distribute pressure, absorb shock, and enhance gait mechanics. Brands integrate these sheets to reduce plantar fasciitis symptoms and improve end-user comfort.

4.2 Bag & Glove Padding

Innovative bag pad designs use memory foam to prevent shoulder fatigue in camera straps and laptop bags . In sports and work gloves, foam inserts provide impact damping and vibration control, protecting hands and wrists during high-intensity activities.

4.3 Wearable Electronics & Soft Robotics

Research explores embedding memory foam within wearable devices and fabric-based logic circuits, leveraging its soft, conformable nature for flexible sensors and “memory” functions in smart garments.

5. Choosing the Right Memory Foam

- Density Matters: 50–90 kg/m³ balances lightness with lifespan; lower densities may degrade faster, while higher densities add bulk and cost.

- Hardness Selection: 70–90 ILD (Asker F) offers medium-soft cushioning; choose lower ILD for plush comfort layers, higher ILD for firmer support.

- Customization: Yongjiu’s facility can tailor sheet thickness (2–50 mm), sheet dimensions (20 m/40 m × 1.4–1.5 m), and add recycled content up to 15 % based on brand specifications.

6. Logistics & B2B Terms

- Shipping: FOB Xiamen (Incoterms 2020)—Yongjiu manages in-country logistics; buyers arrange freight from Xiamen Port.

- Payment:

- Large Orders: 30 % deposit via T/T; 70 % against B/L.

- Small Orders: 100 % T/T or cash on confirmation.

- MOQ: 22.4 m³ (one roll: 40 m × 1.4 m × 0.4 m); custom cuts available.

- Lead Time: 5–7 business days (standard); 7–10 days (custom materials) after sample approval and deposit receipt.

From the original NASA innovation to today’s bio-blended, 3D-printable, and zero-waste variants, memory foam remains at the forefront of comfort technology . Yongjiu’s precision-cut sheets combine proven viscoelastic performance with flexible manufacturing and clear B2B terms, making them the ideal choice for brands and engineers seeking high-performance cushioning, sustainable materials, and reliable supply.